How can Instacart Product Availability Data Scraping Map ZIP Codes With 95% Local Stock Accuracy?

Introduction

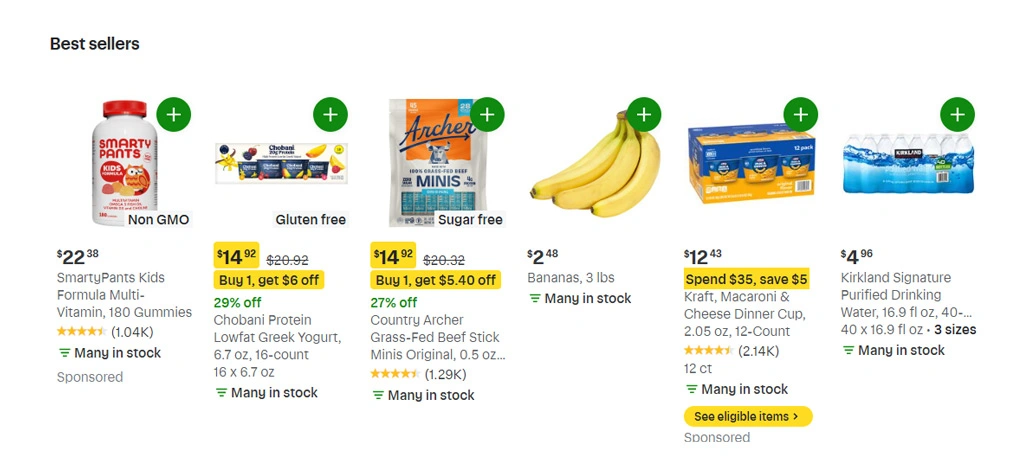

Hyperlocal retail intelligence is no longer optional for grocery brands and quick commerce platforms competing on availability, speed, and consumer trust. Shoppers today expect their favorite SKUs to appear in stock the moment they open an app, especially for time-sensitive grocery orders. However, inventory mismatches between what’s displayed online and what’s actually available at nearby stores often lead to abandoned carts, poor brand perception, and lost revenue.

This is where Instacart Product Availability Data Scraping becomes a powerful market intelligence tool. By systematically capturing live stock data across ZIP codes, retailers and FMCG brands can visualize where products are truly available, which neighborhoods face frequent stockouts, and how inventory distribution impacts hyperlocal demand.

In this blog, we explore how data scraping can map product availability across ZIP codes with up to 95% local stock accuracy, supported by real-world insights, structured analytics, and demand-supply modeling. We’ll also show how this approach transforms inventory planning into a predictive, data-driven process rather than a reactive one. With ZIP-code-level visibility, businesses can move beyond city-wide assumptions and begin optimizing supply at the micro-market level.

Hyperlocal Availability Insights Across Neighborhood Markets

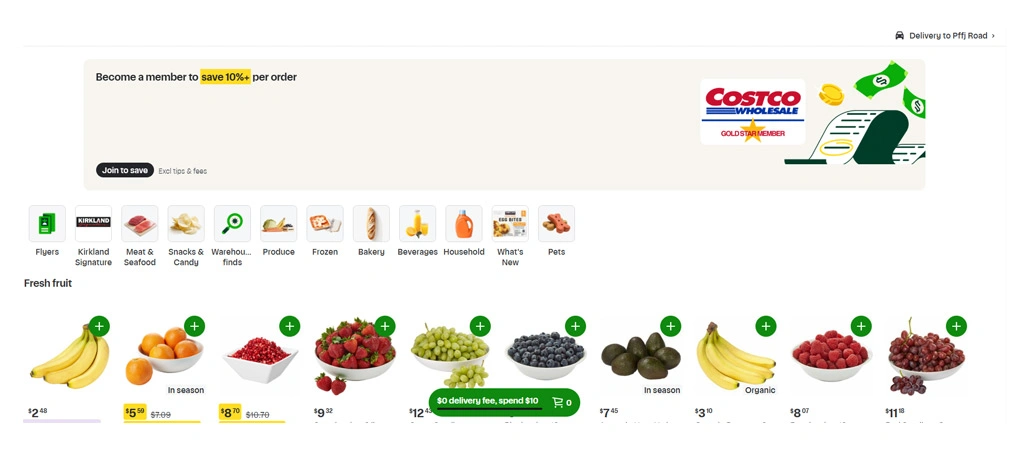

Understanding neighborhood-level stock behavior is critical for grocery retailers operating in on-demand delivery environments. Using Hyperlocal Grocery Availability Analysis Using Web Scraping, businesses can capture real-time SKU visibility from Instacart across thousands of ZIP codes, enabling precise tracking of where products appear in stock and where they vanish unexpectedly.

This hyperlocal view allows retailers to detect Zip Code Level Instacart Availability variations that city-wide reports often miss. For example, two ZIP codes within the same metro area may show dramatically different in-stock rates for identical SKUs, driven by store fulfillment policies, local demand density, and last-mile delivery constraints.

Sample ZIP Code Availability Snapshot:

| ZIP Code | Total SKUs Tracked | In-Stock (%) | Frequent Stockouts | Avg. Delivery ETA |

|---|---|---|---|---|

| 10001 | 3,200 | 96% | 3% | 42 mins |

| 60614 | 2,850 | 92% | 6% | 48 mins |

| 90024 | 3,100 | 95% | 4% | 45 mins |

| 73301 | 2,600 | 89% | 8% | 51 mins |

When combined with Grocery Availability Mapping Data, these insights support better warehouse stocking decisions, smarter fulfillment routing, and targeted regional promotions. Retailers can also compare week-over-week trends to anticipate upcoming stock gaps and rebalance inventory ahead of peak demand windows.

This approach helps brands visualize underserved ZIP codes where strong consumer demand meets frequent stockouts, directly impacting cart abandonment rates. By using Map Instacart Product Availability Using Data Scraping, businesses replace reactive replenishment with proactive inventory alignment strategies that improve shopper trust and long-term loyalty.

Localized Demand Intelligence for Consumer Brands

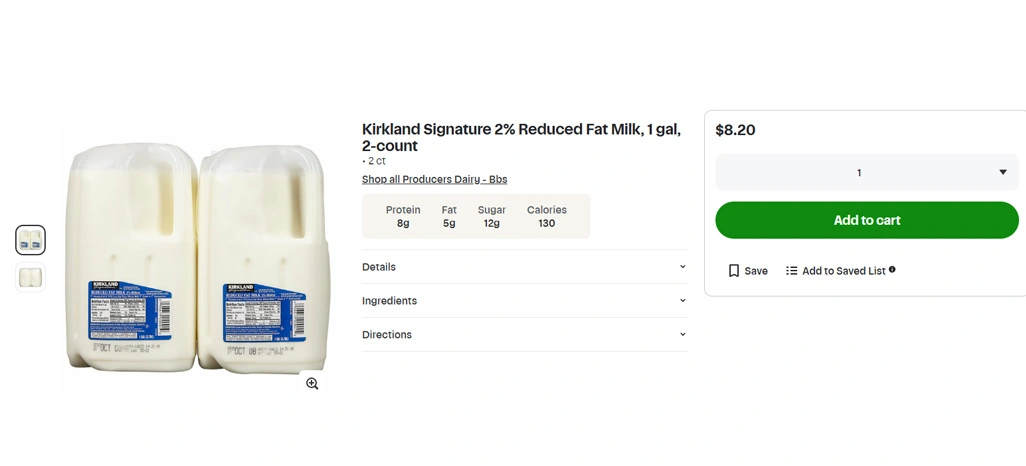

For FMCG brands, visibility into local stock availability is no longer optional—it’s a strategic necessity. With Instacart Data Scraping for Fmcg Brands, manufacturers can track which SKUs appear consistently across ZIP codes and where availability drops undermine regional sales performance.

By monitoring Instacart Inventory Data by Location, brands can correlate stock presence with advertising investments, coupon campaigns, and localized demand spikes. This reveals hidden inefficiencies, such as running digital promotions in ZIP codes where products are frequently unavailable.

Brand SKU Availability vs Demand Index:

| Brand SKU | ZIP Code | In-Stock (%) | Demand Index | Visibility Score |

|---|---|---|---|---|

| Organic Milk 1L | 10001 | 97% | 88 | High |

| Snack Bars Pack | 60614 | 91% | 92 | Medium |

| Pasta Sauce 500g | 90024 | 94% | 90 | High |

| Cold Brew Coffee | 73301 | 86% | 95 | Low |

This data exposes lost revenue opportunities when high-demand SKUs show low visibility in priority ZIP codes. Brands can use these insights to push replenishment requests to retail partners, optimize regional distribution agreements, and adjust production schedules.

It also enables competitive benchmarking. If rival brands maintain better stock consistency across high-traffic ZIP codes, corrective action can be initiated quickly. Using Instacart Inventory Tracking at Zip Code Level, FMCG teams strengthen retailer relationships and align sell-through goals with real-world availability instead of forecast assumptions.

Predictive Models for Smarter Inventory Planning

As grocery delivery becomes increasingly data-driven, forward-looking availability intelligence is becoming a competitive differentiator. With structured Instacart Grocery Delivery Datasets, retailers can move from monitoring stock behavior to predicting future shortages across ZIP codes.

By applying Instacart Data Scraping by Zip Code, analytics teams combine availability trends, delivery slot demand, reorder frequency, and seasonal shopping behavior to build accurate stockout risk models.

Predictive Stockout Risk by ZIP Code:

| ZIP Code | Current In-Stock % | Demand Growth % | Stockout Risk | Replenishment Priority |

|---|---|---|---|---|

| 10001 | 96% | +4% | Low | Medium |

| 60614 | 92% | +7% | Medium | High |

| 90024 | 95% | +5% | Low | Medium |

| 73301 | 89% | +9% | High | Critical |

Using Zip Code Level Grocery Data Scraping, predictive systems can alert inventory teams 24–72 hours before stockouts occur. This enables preemptive restocking, smarter inter-store transfers, and prioritized last-mile delivery routing.

Retailers can also implement dynamic promotions. ZIP codes with surplus stock and low demand can receive targeted discounts, while high-demand ZIP codes get replenishment priority. This data-led approach transforms inventory operations from reactive firefighting into proactive planning, improving service reliability and reducing lost sales across fulfillment zones.

How Retail Scrape Can Help You?

We deliver advanced solutions built around Instacart Product Availability Data Scraping to help brands and retailers achieve hyperlocal stock visibility with up to 95% accuracy.

Our Capabilities Include:

- Real-time ZIP code-level availability tracking.

- Historical trend analysis and demand forecasting.

- Competitor stock benchmarking.

- Predictive stockout modeling.

- Localized promotion intelligence.

- Inventory optimization insights.

By combining scraping technology with analytics, we empower teams to make faster, smarter decisions using Instacart Inventory Tracking at Zip Code Level for operational excellence.

Conclusion

Accurate hyperlocal stock intelligence is reshaping grocery commerce. By implementing Instacart Product Availability Data Scraping, brands and retailers can eliminate blind spots, improve fulfillment reliability, and align inventory with real-world consumer demand.

As ZIP code-level insights become essential for competitive growth, tools like Instacart Data Scraping by Zip Code provide the foundation for smarter retail operations. Connect with Retail Scrape today to turn hyperlocal data into measurable revenue impact.